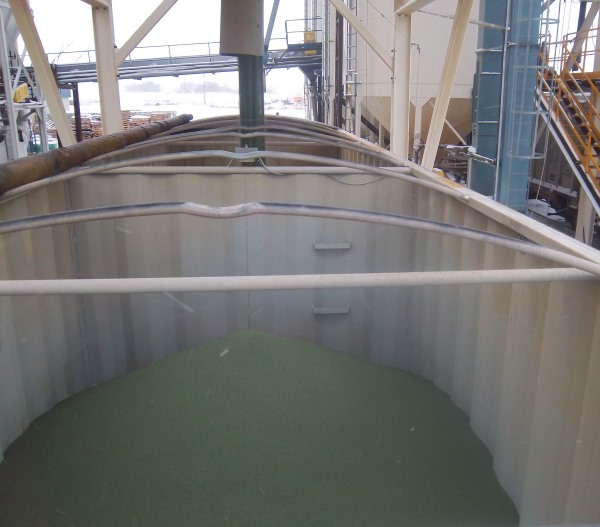

Spillage of sand

Over the last few years the blower volume capacities have increased. Although this helped cut down on unloading time, it’s alternatively led to more spillage and dust.

High and low blower capacities both have their own problems.

Smaller blowers have the issues of “Plugging off”. A plugged line usually means pressuring down and cleaning the line out which means more sand on the ground and lost time. Plugged lines are pressurized making them a serious safety hazard.

Increased blower capacities have a much less chance of plugging off. The downside is they continue to blow the sand out the top lid and over the top of the vessel. Inattentive or inexperienced operators can create quite a mess and increase silica dust in the area. The problem became worse as the jobs got bigger and more vessels were needed. It became difficult to monitor the unloading progress.

Frac Sand Safety. As fracturing jobs got bigger, stacking sand vessels became a challenge for operators of pneumatic systems.

Effects of pressure on specially coated sand

Maximum conductivity is achieved by preserving the quality of the sand. Less fines and silt means reduced turbidity and can translate into millions of dollars in revenue over the life of a well. This makes preserving the quality of curable resin coated sand very important. Telebelting provides a system with no pressure thereby preserving sand quality.

There are 2 main problems with curable resin coated sands and pneumatic systems. The first one is a problem of following directions. It’s clearly noted on each loading ticket that coated sands should be offloaded at reduced pressure. (Maximum pressure of 5 or 6 psi.)

Unloading at a lower pressure prevents the coating from being blown off the sand. If these directions are followed it then doubles the unload time. Unloading a trailer at this rate can easily take 2 to 3 hours.

The second is an issue for not following the directions.

Many drivers either fail to recognize, or ignore these directions and don’t take the proper measures when unloading. This in turn will affect the quality of the product.

Pressurized pneumatic systems unloading under high pressure can strip these curable resin coatings off the sand. A reduction in bonding capability leads to an increase in proppant pack migration, flow back, and a reduced ability to resist cyclic stress.

Frac Sand Safety. Most people think of frac sand like the kind they find at the beach. This is a resin coated frac sand being loaded from the plant.

Advantages of Telebelting over pressurized unloading

Telebelts have been a positive change to the industry by eliminating the hazards of numerous pressurized lines. Eliminating pressure leads to a significant reduction in the health hazards of drifting silica dust. It can also be done with much less spillage.

Preserving curable resin coatings is another benefit over conventional methods as it leads directly to increased well conductivity.

They’re also significantly quieter than PTO driven blowers. These blower units can wake up sleeping workers, medics and consultants. Many locations don’t allow blowers to be operated at night near residential areas. Hearing protection is a must with pneumatic systems.

Safety in the Oil and Gas industry is a high priority and unloading without pressure has been a step in the right direction. Let’s move on to the next section for some more comparisons.